GT precision ceramic filter

Release Time:2024-04-10 10:24:23 Information Source:Home Station Read Times: 0 Time

How it works:

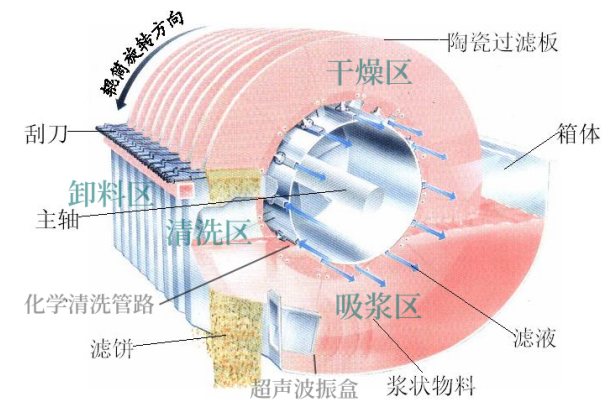

The automatic special ceramic filter works based on the principle of capillary pores, using microporous ceramics as the filter medium, and using a large number of small microporous ceramics with capillary action principle designed solid-liquid separation equipment. Under the working condition of negative pressure, the vacuum in the inner cavity of the ceramic plate is extracted to produce a pressure difference with the outside, so that the suspended material in the tank is adsorbed on the ceramic plate under the action of negative pressure. The solid material cannot be trapped on the surface of the ceramic plate through the micro-porous ceramic, while the liquid can be smoothly discharged or utilized through the gas-liquid distribution device (vacuum barrel) due to the effect of vacuum pressure difference and the hydrophilicity of the ceramic plate. The purpose of solid-liquid separation is achieved.

(Kelvin's law of capillary effect, under the appropriate micropore diameter, the micropore capillary force in the ceramic plate is greater than the force exerted by the vacuum pump, so that the ceramic plate micropores are filled with liquid to achieve the purpose of automatic sealing and blocking the air flow, so that the vacuum pump of the vacuum ceramic filter reaches a state close to vacuum at a low operating power. For the filtration equipment of the vacuum filtration principle, the higher the vacuum degree is, the higher the filtration efficiency and the lower the material moisture.

The rotor (ceramic plate) runs for a week, and the working process is divided into four areas: suction area, drying area, unloading area, cleaning area, repeated cycle, continuous production.

TT series special ceramic filter Features:

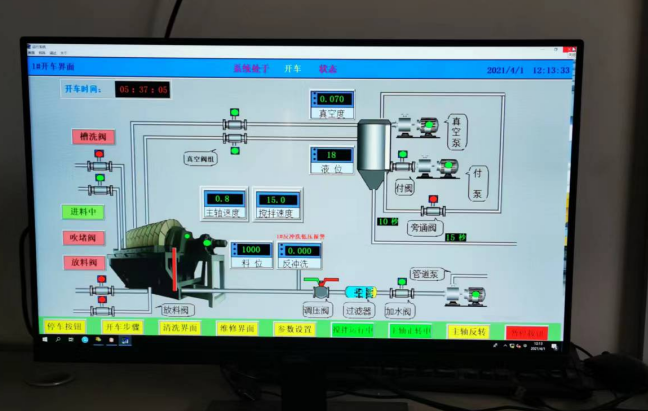

1, high degree of automation, continuous work

The production process is automatically controlled by PLC. It is equipped with human-computer interaction interface, simple operation, manual and automatic, perfect alarm function, and easy to query historical data. Time can be switched to drain liquid level meter. Operation data can be transmitted to DCS system, remote control.

2, high efficiency, energy saving and environmental protection

Low energy consumption and low operating costs. The vacuum pump power is 10% of the traditional equipment energy consumption, high vacuum; The filtrate is clear, in line with China's GB8978-88 environmental protection emission standards and can be fully utilized into the industrial water recycling system, and the solid content has been below 50ppm, which can be recycled. The cake is dry and the moisture is adjustable. The yield is 2-4 times higher than the traditional equipment, and the effective recovery rate of concentrate is increased by 0.2-0.5%.

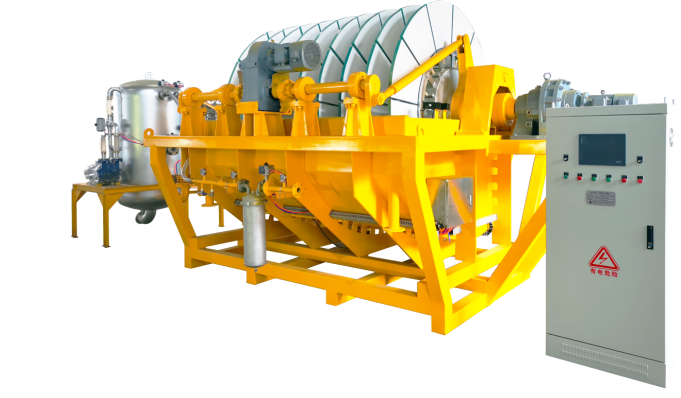

3, the machine structure is strong, durable

The material of the contact part of the equipment and the material is not less than 304 stainless steel.

The spindle and mixing are regulated by frequency conversion. Ceramic plate adopts integral flange ring installation, smooth.

Mixing system can be configured according to the specific gravity of the material pneumatic, mechanical swing and combined mixing, firm.

4, integrated drainage system is convenient

Automatic drainage system adopts integrated drainage tank, low failure rate and easy installation. The drainage system can choose to switch between liquid level drainage and time drainage, which is convenient for maintenance.

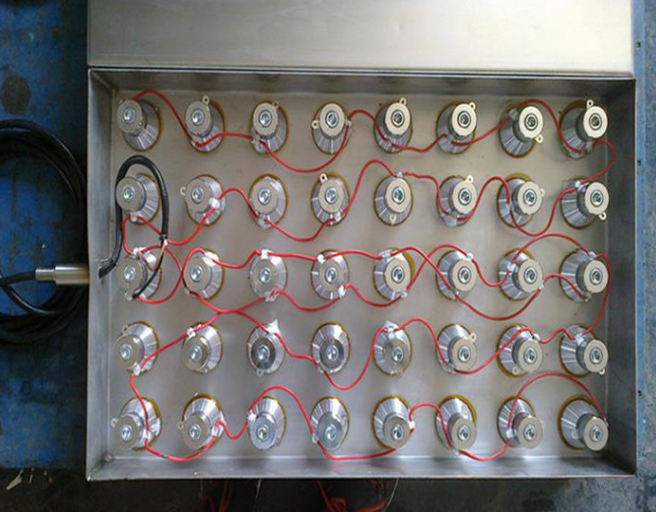

5. Joint cleaning is effective

According to the different particle size of the material, the company has configured ultrasonic cleaning devices with different frequencies of 20K,25K,28K and 40K. In view of the blockage caused by different physical and chemical properties of the filter plate, the company has developed a special immersion agent, a multi-vibrating head cleaning machine and a cleaning program for regenerative cleaning, so that the filter plate microhole dredging can reach more than 80%.

6, ceramic plate performance is good

It has the characteristics of uniform and controllable pore size distribution, high porosity, good water permeability and high compressive strength. With 8 craft kilns, any type of ceramic plate can be produced and customized.

TT series ceramic filter application range

TT type special ceramic filter produced by our company has been widely used in gold, silver, copper, iron, tin, lead, zinc, nickel, cobalt, palladium, molybdenum, chromium, sulfur, phosphorus, coal ash xi, silicon, quartz, mica, rare earth and other concentrates, tailings dehydration; Chemical industry for zinc oxide, lead oxide, zinc sulfide, electrolytic slag, leaching slag, slag, coal slag and derived iron powder, carbon powder, silver powder and other dehydration; Environmental protection industry for sewage sludge waste acid treatment. Material fineness from -200 mesh to -450 mesh and a variety of ultrafine materials.

Technical parameters of TT series ceramic filter

Name/Specification | TT-4 | TT-8 | TT-12 | TT-15 | TT-18 | TT-21 | TT-24 | TT-30 | TT-36 | TT-40 | TT-45 | TT-60 | TT-80 | TT-100 | TT-120 |

Filter plate size (㎡/ circle) | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 5 | 5 | 5 | 5 | 5 | 6 |

Number of filter plates (pieces) | 24 | 48 | 48 | 60 | 72 | 84 | 96 | 120 | 108 | 95 | 108 | 144 | 192 | 240 | 240 |

Number of discs (circles) | 2 | 4 | 4 | 5 | 6 | 7 | 8 | 10 | 9 | 8 | 9 | 12 | 16 | 20 | 20 |

Filter area (㎡) | 4 | 8 | 12 | 15 | 18 | 21 | 24 | 30 | 36 | 40 | 45 | 60 | 80 | 100 | 120 |

Installed power (Kw) | 7.6 | 8.8 | 9.2 | 12.1 | 12.5 | 12.9 | 15.8 | 19.75 | 22.58 | 24.85 | 25.45 | 35.4 | 49 | 63.9 | 81.9 |

Operating power (Kw) | 6.6 | 7.4 | 7.4 | 9.9 | 9.9 | 9.9 | 12.4 | 15.55 | 19.05 | 19.85 | 19.85 | 28 | 39 | 51.5 | 67.5 |

Weight (Kg) | 2000 | 3000 | 5000 | 5500 | 6000 | 6500 | 7500 | 9000 | 9700 | 11500 | 11500 | 13800 | 18500 | 21500 | 24500 |

Length L (mm) | 2460 | 2960 | 3200 | 4300 | 4600 | 4900 | 5200 | 5800 | 5110 | 4870 | 5170 | 6600 | 7990 | 9190 | 9190 |

Width W (mm) | 2480 | 2800 | 3080 | 3100 | 3100 | 3100 | 3170 | 3170 | 3435 | 3450 | 3450 | 3450 | 3720 | 3720 | 3850 |

Height H (mm) | 2100 | 2100 | 2450 | 2490 | 2490 | 2490 | 2530 | 2530 | 2820 | 2900 | 2900 | 2900 | 2960 | 2960 | 3180 |

External drawing

Material filtration water parameter table

mineral species | Particle size distribution | Radius concentration% | yield kg/㎡.h | hydration% |

Iron concentrate | ﹣200目占52% | 45~65 | 500~1000 | 7~10 |

Sulfur concentrate | ﹣200目占75% | 40~55 | 400~800 | 10~13 |

Copper concentrate | ﹣200目占33% | 40~55 | 400~600 | 10~15 |

Gold concentrate | ﹣200目占74% | 40~55 | 300~450 | 11~13 |

Zinc concentrate | ﹣200目占99% | 45~55 | 500~700 | 12~13 |

Zinc concentrate | ﹣200目占30% | 45~65 | 550~700 | 10~13 |

Phosphorus concentrate | ﹣400目占92% | 45~55 | 300~400 | 13~15 |

Cyaniding ore | ﹣325目占83% | 40~55 | 350~550 | 25~27 |

Iron tailings | ﹣200目占83% | 45~55 | 350~600 | 11~13 |

Copper tailings | ﹣400目占90% | 45~55 | 350~450 | 11~15 |

Molybdenum tailings | ﹣200目占80% | 50~55 | 350~450 | 12~15 |

Phosphorus tailings | ﹣400目占80% | 50~60 | 350~700 | 12~15 |

Quartz tailings | ﹣200目占80% | 40~55 | 300~350 | 13~15 |

Potash feldspar | ﹣180目占70% | 40~55 | 300~350 | 12~15 |

Note: The above data is for reference only. Due to the different properties of the same material in different regions, the actual yield and moisture are subject to the test data. | ||||