Ceramic filter plate

Release Time:2024-04-12 09:51:26 Information Source:Home Station Read Times: 0 Time

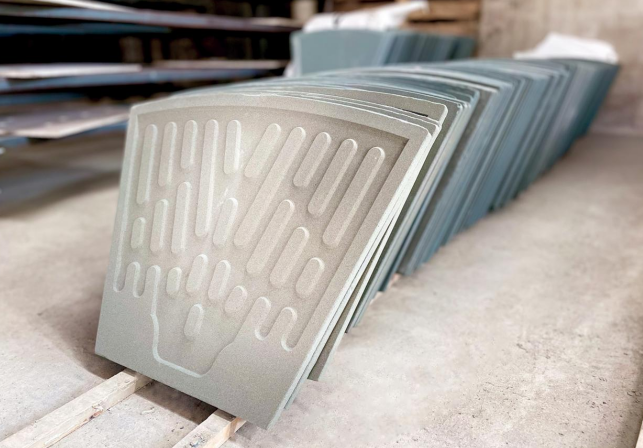

TT series ceramic plates are made of Al203 or SiC materials with high mechanical strength, excellent corrosion resistance and good wear resistance. After adding part of inorganic binder and pore-forming agent, using hydraulic gradient dry pressing and precision machining, using a good process to spray the alumina film surface with micron aperture, and secondary sintering at 1500 ~ 1800℃ to form a porous ceramic plate with double-sided filter layer with pressure resistance of up to 8bard.

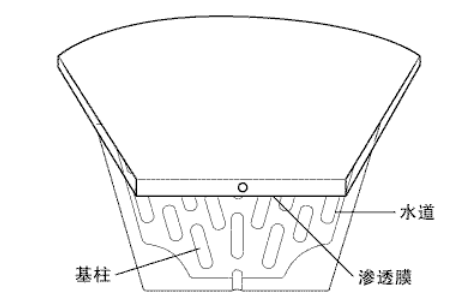

How it works:

Because this porous material contains numerous tiny capillaries, capillary action is possible. Due to its capillary force in the filtration process, only water can pass through the filter plate in the whole process, and the air can not pass through, so as to complete the filtration task, and the vacuum degree can reach more than -0.097Mpa. Low requirements on vacuum pump pumping capacity.

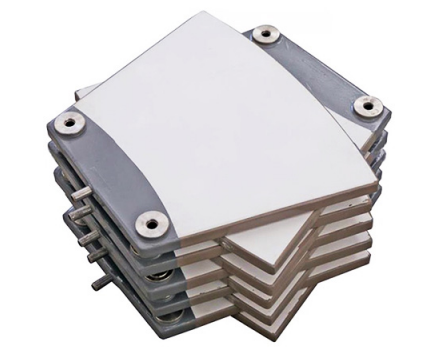

Adhesive composite board

Cast monolithic plate

Features:

1, the skeleton density is large, the film layer strength is high, pressure resistance and corrosion resistance, not easy to damage.

2, high porosity, large production capacity; High filtration accuracy, low vacuum energy consumption; The material is fine and the plasticity is strong. Our company now has the adhesive composite board process and the whole sintering one board process.

3, regeneration methods, can use high temperature and high pressure, organic solvents and other cleaning, regeneration effect is good, the service life is greatly extended.

TT series ceramic filter plate technical parameters

Ceramic plate composition

TT series ceramic filter plate main technical parameters reference table

Product name | Ceramic filter plate | Reserve note | ||

specification | 1㎡、2㎡、3㎡、4㎡、5㎡、6㎡ | Filter membrane and substrate combination can be selected for different filter materials and filter media to achieve filtration effect. | ||

Filter substrate material | White alumina, brown alumina, silicon carbide | |||

Filter micropore size range | 1μm、2μm、5μm、8μm、10μm、15μm | |||

Technical parameters of ceramic filter plate | ||||

item | parameter | |||

Water flux (water pressure is 0.15MPa) | ≥6400L /h·㎡ | |||

Air backwash test pressure (wet) | ≥0.5Mpa | |||

Run backwash pressure | ≥0.12MPa | |||

Ultrasonic combined with chemical cleaning pressure | ≥0.1MPa | |||

Assembly accuracy | The assembly plane of the assembly ring is parallel to the surface of the plate | ±0.2mm | ||

Distance between the assembly plane and the plate surface of the assembly ring | 8±0.1mm | |||

Assembling accuracy | Assembly hole midpoint and diagonal error | ≤2mm | ||

Fit each plate into a disc spacing | 5±1mm | |||

Accumulated time of normal wear resistance of the film surface (not damaged by scrapers or other hard objects) | ≥7000h | |||

porosity | ≥42% | |||

Flexural strength | ≥30MPa | |||